A better board

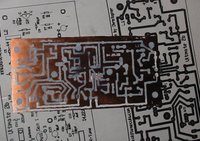

My first PCB was not successful, so here is try number two: As you see here, my I wrapped the copper-coated board more closely than before to ensure maximum contact between iron and board as well as supposedly guranteeing a minimum of shifting. So, after repeating the process from before (see previous post for board creation process), I wound up with the following:

My first PCB was not successful, so here is try number two: As you see here, my I wrapped the copper-coated board more closely than before to ensure maximum contact between iron and board as well as supposedly guranteeing a minimum of shifting. So, after repeating the process from before (see previous post for board creation process), I wound up with the following: As you can see from the large amount of bright white traces on the bottom, the silkscreen transfer was not very successful on the bottom side of my board. I believe this is due in part to the papers that were wrapped too tightly around the board, because I certainly ironed down on the board hard enough to make a successful transfer. After fixing the weak traces with white-out, I dropped the board into the etchant in this plastic bowl.

As you can see from the large amount of bright white traces on the bottom, the silkscreen transfer was not very successful on the bottom side of my board. I believe this is due in part to the papers that were wrapped too tightly around the board, because I certainly ironed down on the board hard enough to make a successful transfer. After fixing the weak traces with white-out, I dropped the board into the etchant in this plastic bowl.It took me 4 hours to completely remove all the copper. It was about 60-65 degrees outsidethat night, and I had the fan on because of the fumes. I would imagine the best place to etch would be outside in 70+ degree weather.

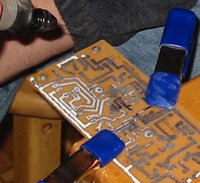

I used small rubber PC motherboard spacers to keep the board off the bottom of my large plastic bowl (picture after etching):

Next came the drilling, with a 1/32" bit this time. The only place I could find a 1/32" bit was in a little drill-bit set for sale at Home Depot. The 6-piece set was marked and sold specifically for Dremels, so I don't know if I paid too much for them because of that. It was approxiamately $7.50.

Next came the drilling, with a 1/32" bit this time. The only place I could find a 1/32" bit was in a little drill-bit set for sale at Home Depot. The 6-piece set was marked and sold specifically for Dremels, so I don't know if I paid too much for them because of that. It was approxiamately $7.50.  Finally, after drilling and buffing the excess ink and white-out off the board, the (new and revised!) etching process, was finished!

Finally, after drilling and buffing the excess ink and white-out off the board, the (new and revised!) etching process, was finished!

3 Comments:

Hi i am interested in building a theremin too. great job so far!

i have some experience in building guitar effects and now i'm starting to be heavily interested in synths.

I use the glossy photo paper too to mark the traces in my boards before etching. In my experience the "wrapping method" is wrong: the best way to make a clean board is to PREheat the copper BEFORE applying the paper. i usually iron it for 3 or 4 minutes at high temperature before applying the paper.

sry for the bad english (i'm italian :)) marco

Hi Dan,

Do you still have the PCB layout document from the old temecula website. A lot of RS theremin information was removed from the website a few years back, I have contacted Chris but with no reply. any help would be appreciated.

Hi Matt,

Sorry but I do not have the PCB layout document any more. Originally, I did this as a college project, so if I find my old files I should be able to scan and re-upload. Thanks for the interest, and let me know if you have any luck getting them elsewhere!

-Dan

Post a Comment

<< Home